The History & Evolution of Buffer Rings: How PTFE Transformed Hydraulic Seal Design

Hydraulic sealing technology has come a long way since the early days of heavy equipment engineering. In high-pressure systems — like those found in construction, mining, and agricultural machinery — seal performance directly impacts efficiency, reliability, and equipment longevity.

When seals fail, the result isn’t just a small oil leak; it can mean costly downtime, safety hazards, and extensive field repairs.

That’s why the development of the buffer ring marks such a pivotal moment in the history of hydraulic seal design. This simple yet ingenious component helped solve one of the industry’s biggest challenges: protecting critical seals from damaging pressure spikes, heat, and extrusion — all while extending system life and maintaining leak-free performance.

At Eclipse Engineering, we see the buffer ring as a turning point in modern sealing systems. The same principles that made it revolutionary in the 1970s still guide how we design and manufacture custom PTFE seals, U-cups, and buffer rings today.

Our engineers continue to refine materials, profiles, and manufacturing processes to deliver high-performance sealing solutions for hydraulic systems operating in the most demanding conditions.

In this post, we’ll explore the origins of the buffer ring, how it works, and why its design forever changed the way engineers think about hydraulic sealing solutions.

Why the Buffer Ring Revolutionized High-Pressure Hydraulic Seal Design

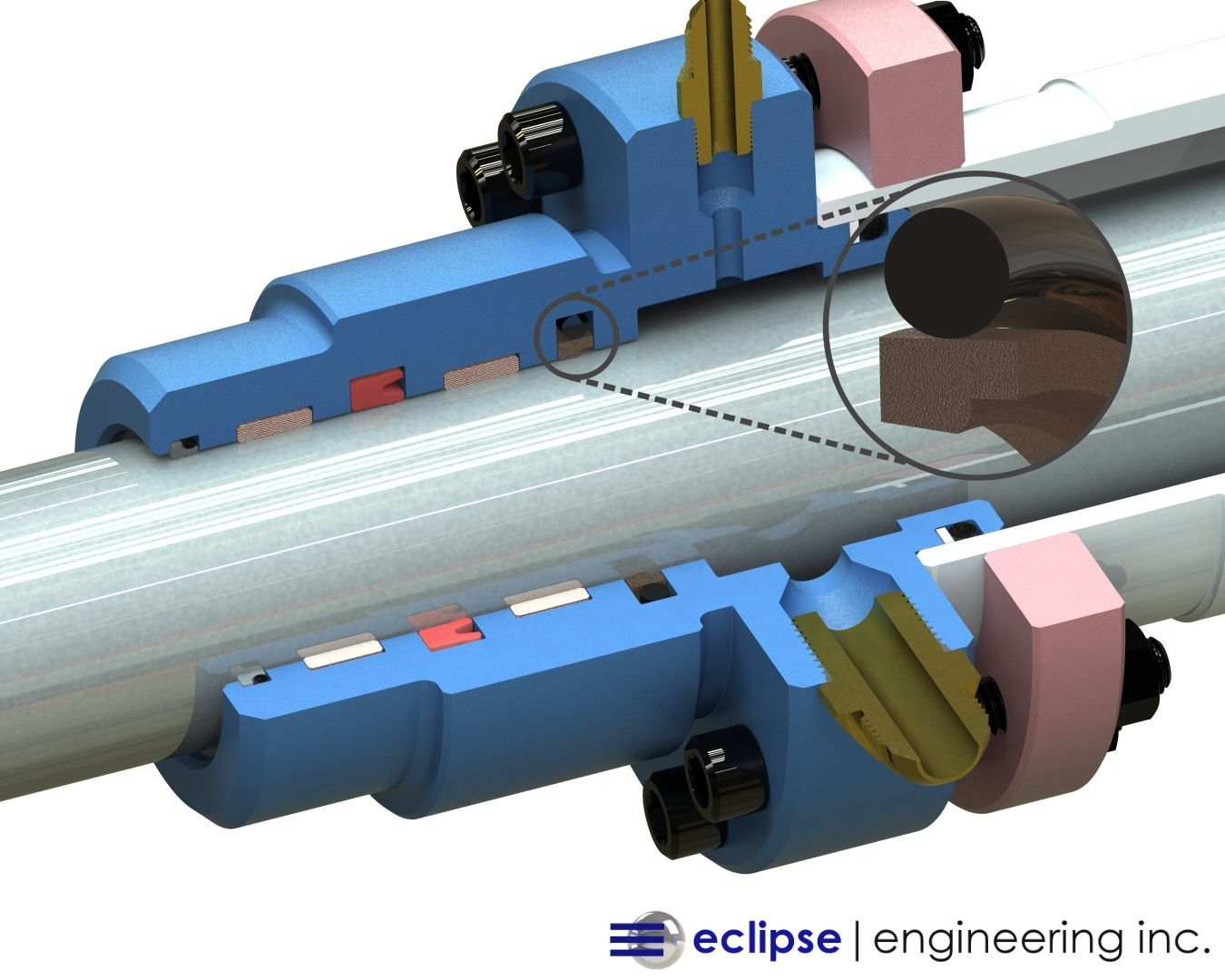

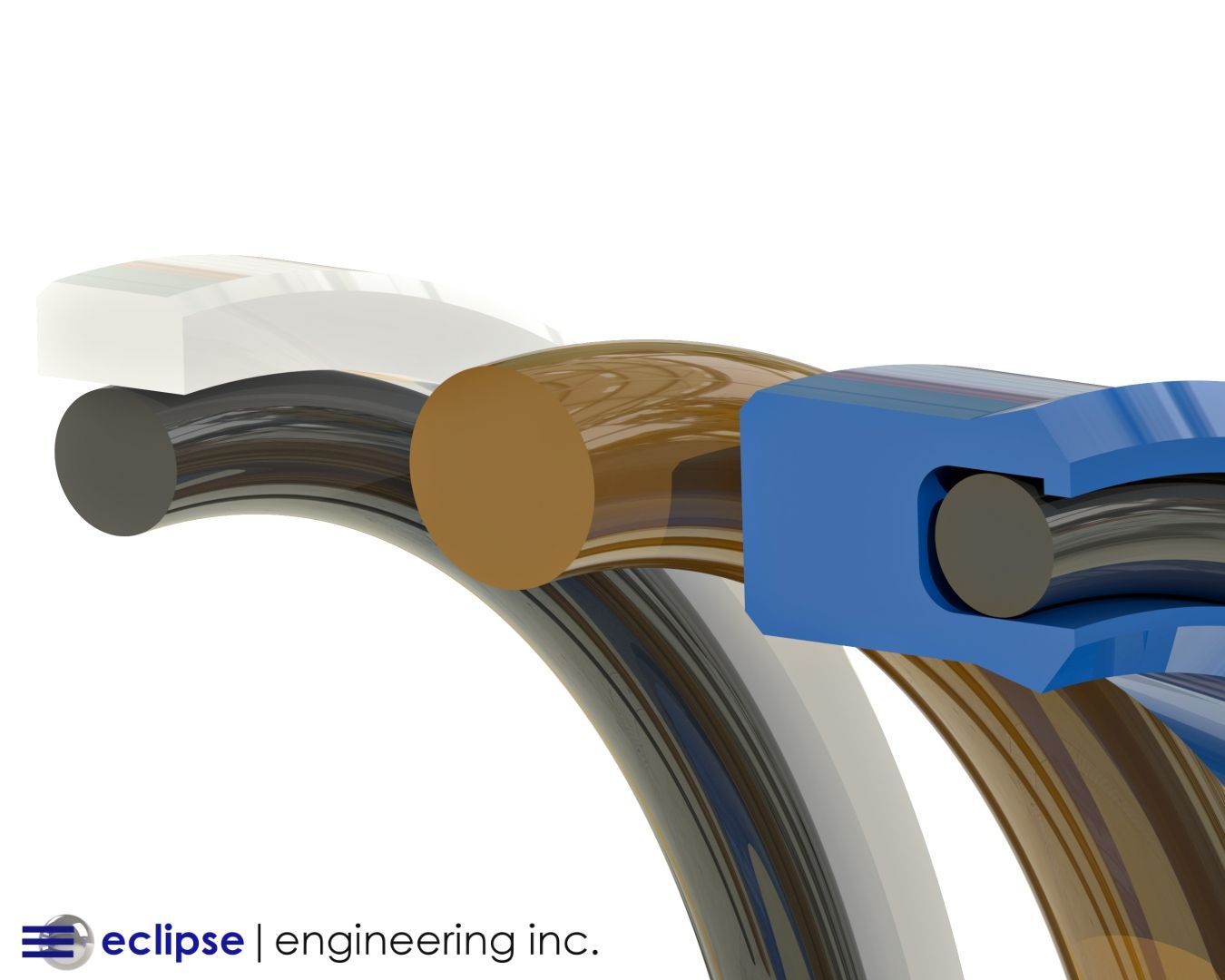

Back in the mid-1970s, an engineer named Roy Edlund of Busak & Luyken designed a high-pressure seal with an unexpected but revolutionary behavior: it would rock in the groove under pressure. This effect occurred when the rod was retracted into the cylinder, creating pressure on the retract side.

The material used for this innovative seal was a bronze-filled PTFE (Teflon®) — a material that could resist extrusion and provide long seal life. However, because the seal was made from filled Teflon, a small amount of oil would leak under the lip as the cylinder extended.

Surprisingly, this wasn’t a flaw — it was a feature. When the rod retracted, the buffer ring would rock slightly to the low-pressure side, forcing leaked oil back into the retract side of the cylinder.

This self-correcting motion not only reduced leakage but also extended the life of hydraulic seals, transforming how engineers approached high-pressure hydraulic sealing systems.

Today, this component is known as the Buffer Ring, and it helped usher PTFE seals into nearly every high-pressure hydraulic application we see today.

Pre-Buffer Ring Sealing Problems

Before the advent of the buffer ring, manufacturers of high-pressure hydraulic systems—like those used in backhoes, cranes, and heavy machinery—were facing frequent seal failures long before their warranty periods ended.

The standard urethane U-Cup seal performed adequately at moderate pressures, creating a near-zero-leak system under normal conditions. However, as bulk oil temperatures rose and pressure spikes occurred, these seals would degrade rapidly.

Common Problems Before Buffer Rings:

- Pressure spikes causing urethane to crack and fail prematurely

- Heat buildup accelerating material wear

- Frequent downtime and costly field repairs for OEMs

- Inefficient energy use due to internal leakage and friction

These issues didn’t just shorten seal life — they affected entire hydraulic system performance, leading to increased maintenance costs and reduced operational efficiency.

The Buffer Ring Solution

The Buffer Ring addressed these issues with remarkable simplicity. By adding a secondary sealing element in front of the U-Cup, engineers could dramatically reduce pressure spikes, lower system friction, and extend seal life.

This dual-seal configuration acted as both a pressure buffer and a lubrication regulator, allowing a controlled amount of oil to reach the U-Cup for cooling and reduced friction.

Key Benefits of Buffer Rings:

- Extends U-Cup life by reducing pressure load

- Lowers bulk oil temperature in the hydraulic system

- Reduces system friction for smoother operation

- Improves equipment uptime and lowers warranty costs

The results were clear: longer-lasting seals, fewer failures, and lower maintenance costs — a combination that quickly made PTFE buffer rings a staple in hydraulic cylinder design.

How the Buffer Ring Works

At first, many engineers were skeptical. How could placing one seal in front of another reduce pressure without creating a trap?

The answer lies in the controlled leakage mechanism that defines buffer ring design.

The Science Behind It:

- The buffer ring intentionally allows micro-leakage, ensuring the U-Cup remains lubricated.

- This leakage prevents heat buildup and material degradation.

- During retraction, the buffer ring “rocks” slightly, pushing oil back into the system — maintaining balance and preventing trapped pressure.

This unique dynamic allows the U-Cup to operate in a low-pressure, low-temperature, and well-lubricated environment, dramatically extending its operational life.

For hydraulic cylinder manufacturers, the buffer ring meant higher reliability and fewer field failures — all while simplifying maintenance protocols.

Why Material Selection Matters in Buffer Rings

While early buffer rings used bronze-filled Teflon, modern versions leverage advanced polymer blends that improve flexibility, wear resistance, and compatibility with different fluids.

Common Buffer Ring Materials:

- Bronze-filled PTFE: Excellent wear and extrusion resistance for high-pressure applications.

- Glass-filled PTFE: Improves stiffness and temperature performance.

- Carbon-filled PTFE: Reduces friction, ideal for dynamic sealing.

- UHMWPE or PEEK composites: Used in extreme pressure or chemical environments.

Choosing the right material depends on the operating pressure, temperature, media, and motion type (static, reciprocating, or rotary). Eclipse’s in-house engineers often customize these materials to achieve optimal seal performance and longevity.

Comparing Buffer Rings to Other Hydraulic Seals

While buffer rings are critical in high-pressure hydraulic applications, they serve a distinct purpose compared to other seals.

| Seal Type | Primary Function | Typical Material | Advantages | Disadvantages |

|---|---|---|---|---|

| U-Cup Seal | Prevents fluid leakage | Urethane, Nitrile | Excellent sealing, flexible | Vulnerable to pressure spikes |

| O-Ring Seal | General-purpose sealing | Nitrile, Viton | Simple, inexpensive | Not suited for dynamic or high-pressure systems |

| Buffer Ring | Protects primary seal from pressure spikes | PTFE Blends | Pressure relief, lubrication control | Requires precise groove design |

| Rod Seal | Prevents fluid escape from rod side | PTFE, Rubber | Ensures dry rod surface | May need backup rings for pressure handling |

This comparison illustrates how the buffer ring acts as a pressure regulator, rather than a primary barrier — a distinction that has made it indispensable in modern hydraulic seal systems.

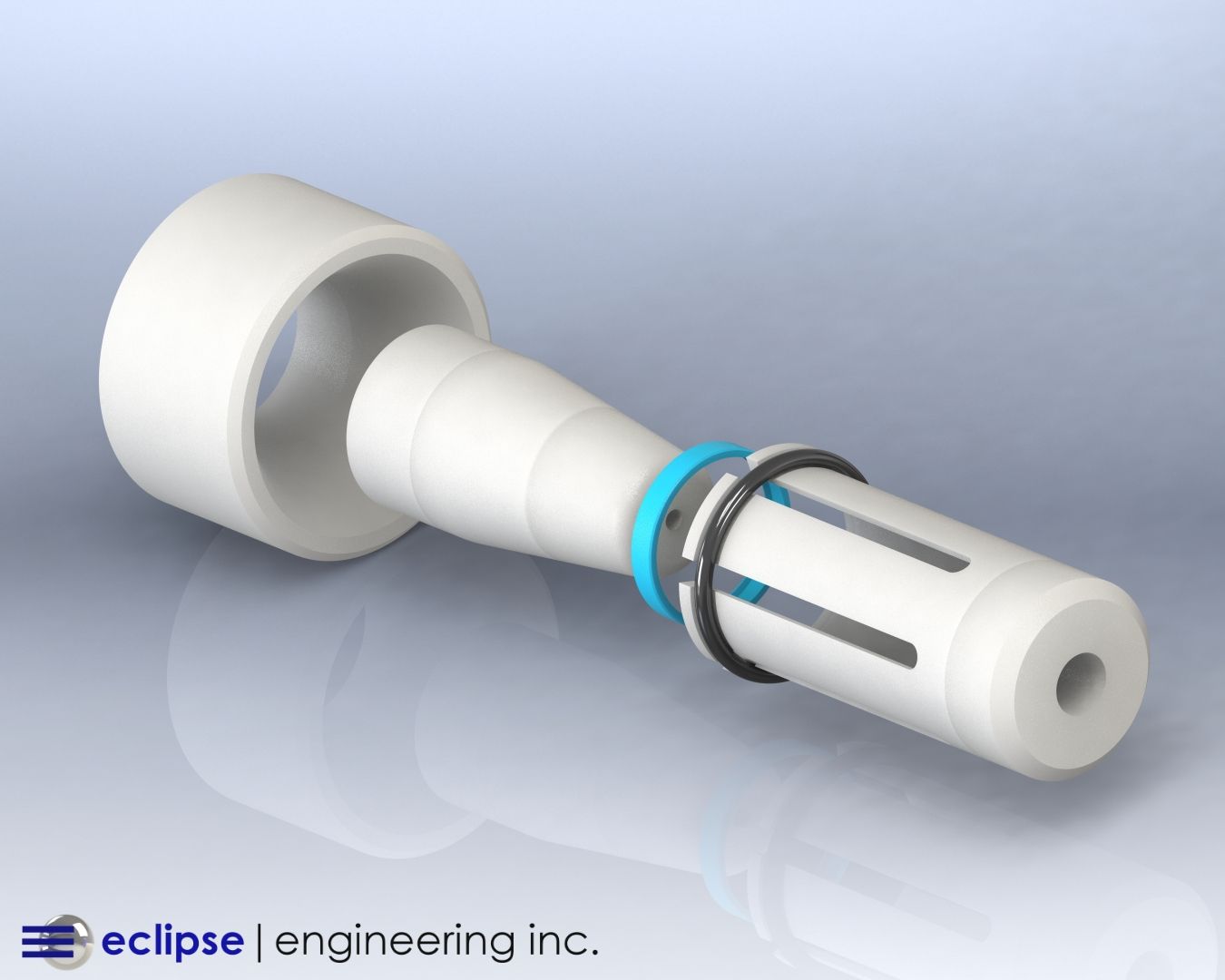

Design Considerations for Hydraulic Buffer Rings

To ensure optimal performance, buffer rings must be carefully matched to the system’s design parameters.

Key Design Factors:

- Groove geometry: Must allow slight rocking and oil return flow.

- Surface finish: Polished to minimize friction and leakage.

- Temperature and pressure range: Ensure compatibility with seal material.

- Lubrication path: Must support oil return to maintain seal life.

At Eclipse Engineering, these factors are analyzed during the seal design process, ensuring that every hydraulic sealing package meets or exceeds system requirements.

The History and Legacy of the Buffer Ring

The Buffer Ring began as a patented design under the name Stepseal®, owned by Trelleborg. Though the original patents have long since expired, the design remains a cornerstone in modern hydraulic sealing technology.

Refinements, like removing the corner heel to prevent extrusion in ultra-high-pressure systems, have kept this design relevant for nearly 50 years.

Today, Eclipse continues to evolve this technology through custom seal design, advanced materials, and precision manufacturing in Erie, Colorado — ensuring each solution meets demanding application needs.

Eclipse Engineering: Custom Buffer Rings for Modern Hydraulic Systems

At Eclipse Engineering, we design and manufacture custom buffer rings, U-cups, and bearings for hydraulic cylinders and actuators across industries — from aerospace to heavy equipment.

Our engineers can develop a complete sealing solution tailored to your system’s unique needs, using the right blend of PTFE, polymer composites, and energizers to achieve the perfect balance of sealing reliability and cost efficiency.

All Eclipse products are manufactured in the USA, combining decades of experience with cutting-edge sealing technology.

Ready to improve your hydraulic system performance?

Contact Eclipse Engineering today to speak directly with an engineer about your application.