Aside from ball valve seats or non-contact labyrinth seals, PTFE is rarely used without a secondary energizer. This is due to PTFE’s inelastic nature. Unlike urethanes or elastomers which possess an inherent springiness, PTFE is often considered an “unalive” material. Much like a lump of clay, it will not bounce back once deformed.

Especially in dynamic applications, this is not a desirable quality. Fortunately, with the addition of a spring or elastomer energizer, all of PTFE’s excellent attributes can be fully exploited in terms of sealing.

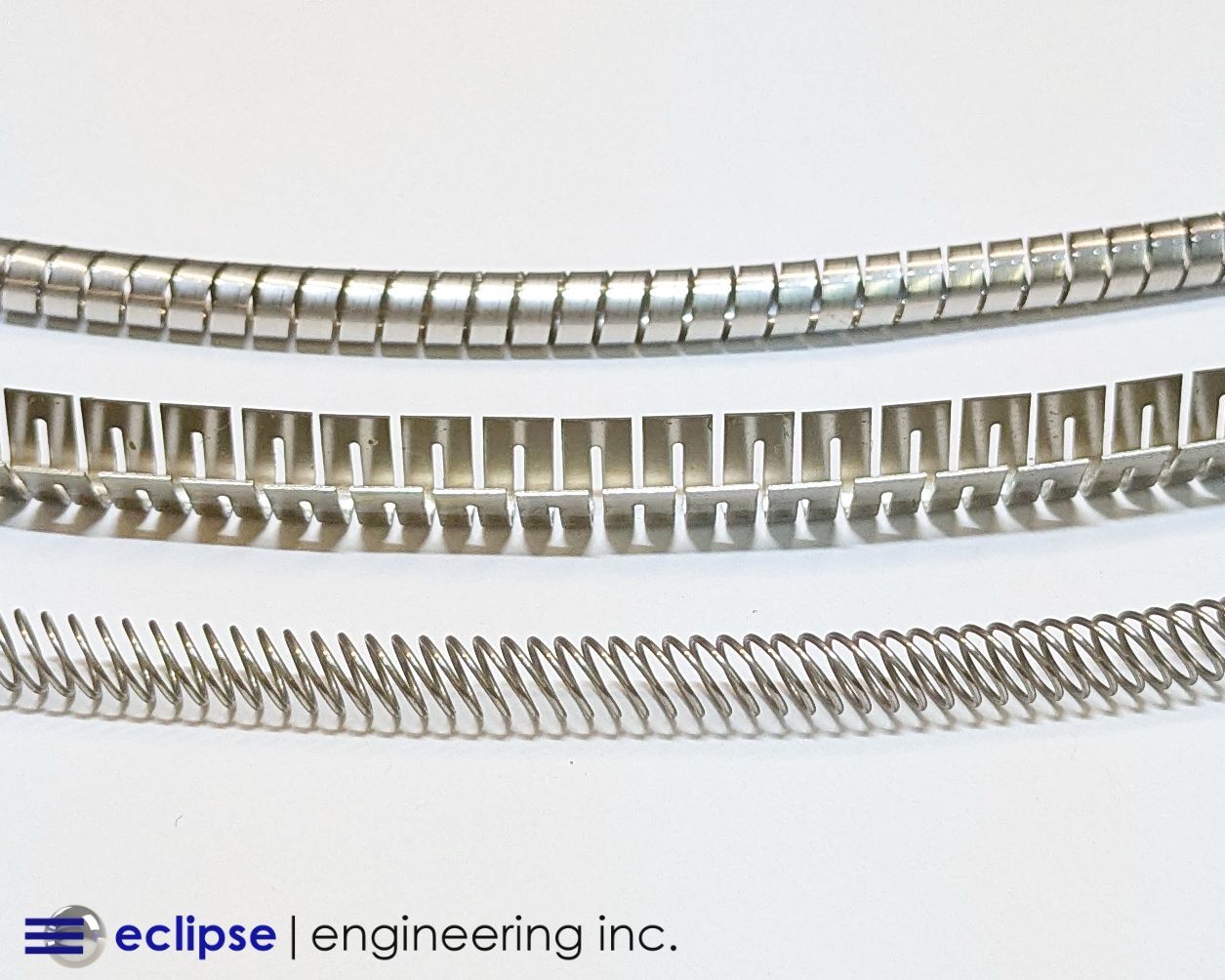

Much like the rest of the seal industry, Eclipse utilizes three metallic spring energizer types for the seals we manufacture. Canted Coil, Cantilever V-Spring, and Helical. While each spring type ultimately accomplishes the same task, energizing a PTFE or polymer seal jacket, we’ll see that each type has unique properties better suited to certain applications.

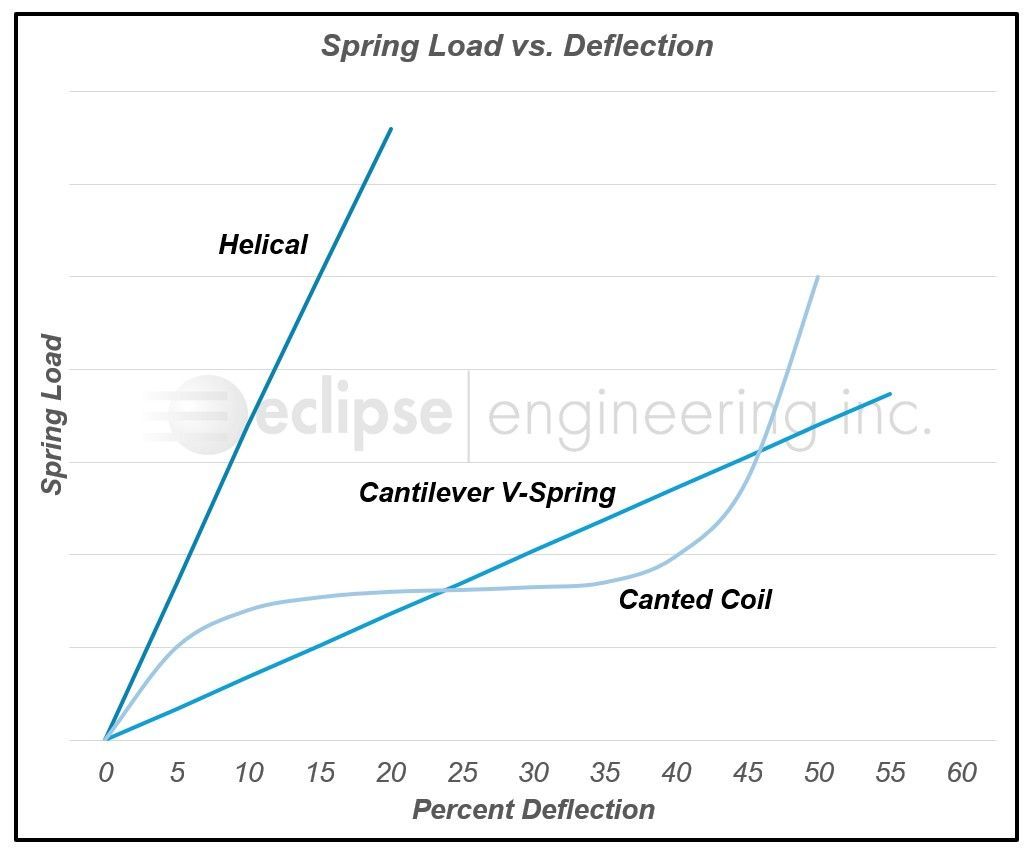

Figure 1 below shows generalized load versus deflection curves for the three spring types. As you can see, each one is quite a bit different, favoring distinct circumstances and applications. Though, we’ll also find out load curves are not only deciding factor when choosing a spring.

Canted Coil

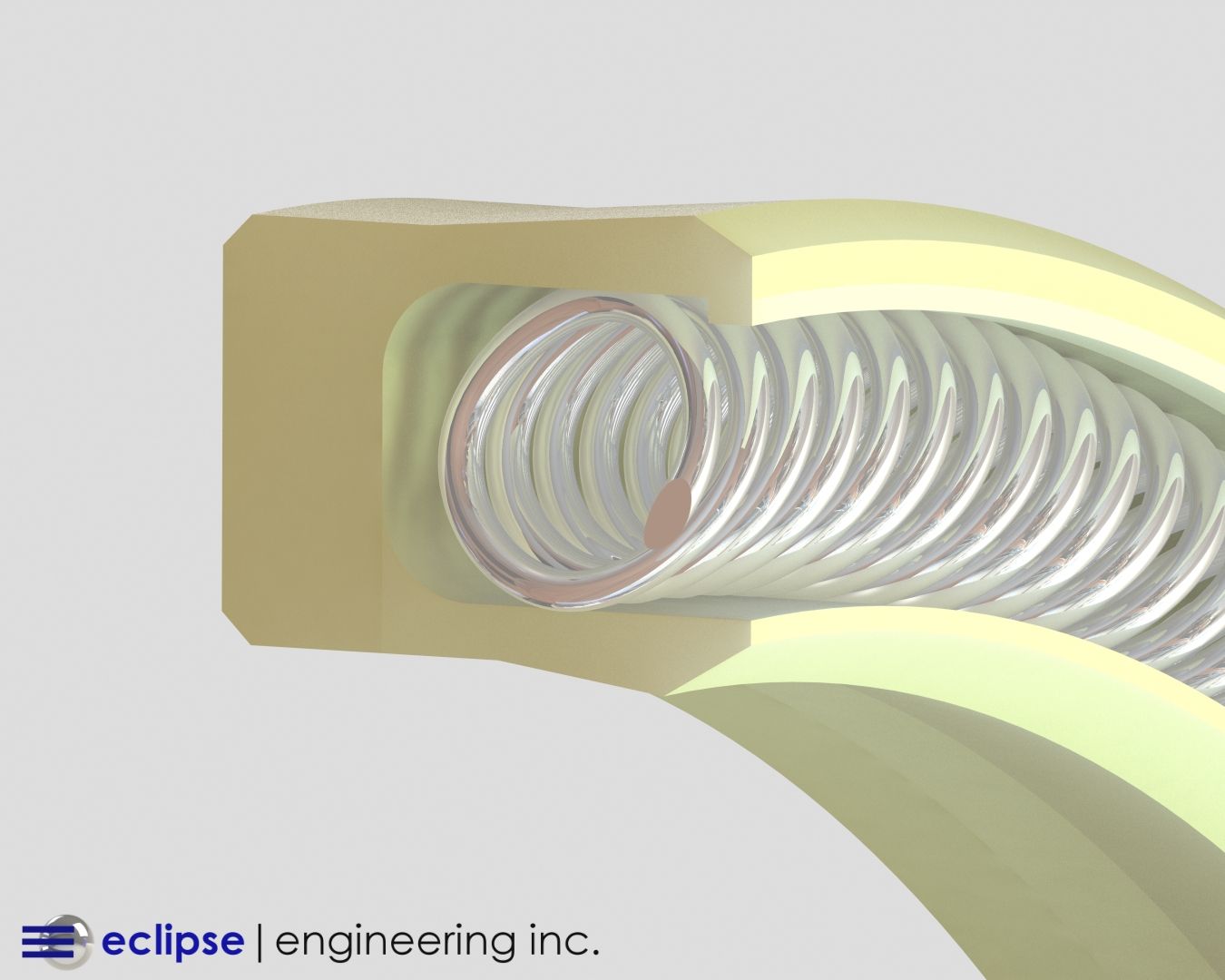

Canted Coil spring is similar to a standard round wire coil spring except the coils are canted at angle to one side. The spring takes on an oval, or elliptical shape with a minor and major axis. If formed into a circle, as in a rod or piston seal jacket, the canted coils allow the spring to be compressed on the minor axis in the radial direction.

Eclipse manufactures its own canted coil spring in the standard seal series cross-sectional sizes. Eclipse cuts to length and laser welds all of its canted coil spring in house, ensuring the best quality control and customization possible.

Canted Coil’s claim to fame is its very unique load curve. As shown in Figure 1, there is a large portion of its deflection range where the spring load remains nearly constant. This is in contrast to the other spring types which exhibit linear load curves where more deflection equals more load.

Canted Coil spring seals are designed to work in this constant load range providing the seal with stable, predictable spring force throughout the course of its wear-life. Unlike other spring types with linear load curves, spring force will not be reduced as the seal wears.

This is a distinction among the spring types, as cantilever and helical spring can be destructively yielded if over compressed. In applications where there is potential for the seal to see a back-pressure situation, canted coil might be the best choice. A canted coil seal will likely return to operational despite seeing significant pressure in the opposing direction. Cantilever and helical spring have the potential to yield resulting in a failed seal.

Canted coil’s robustness can also be an advantage in complex gland configurations where seal installation is not straight-forward. Though it typically is not recommended, it is possible to install a canted coil seal into a solid gland if the diameter is large enough compared to the cross-section. Solid gland installation is never advised with the other spring types due to the possibility of damage.

Canted coil is also the spring of choice for very small seal applications. Eclipse has made canted coil seals with ID’s as small as 1mm. V-Spring and helical have physical limitations on inner diameters.

Cantilever V-Spring

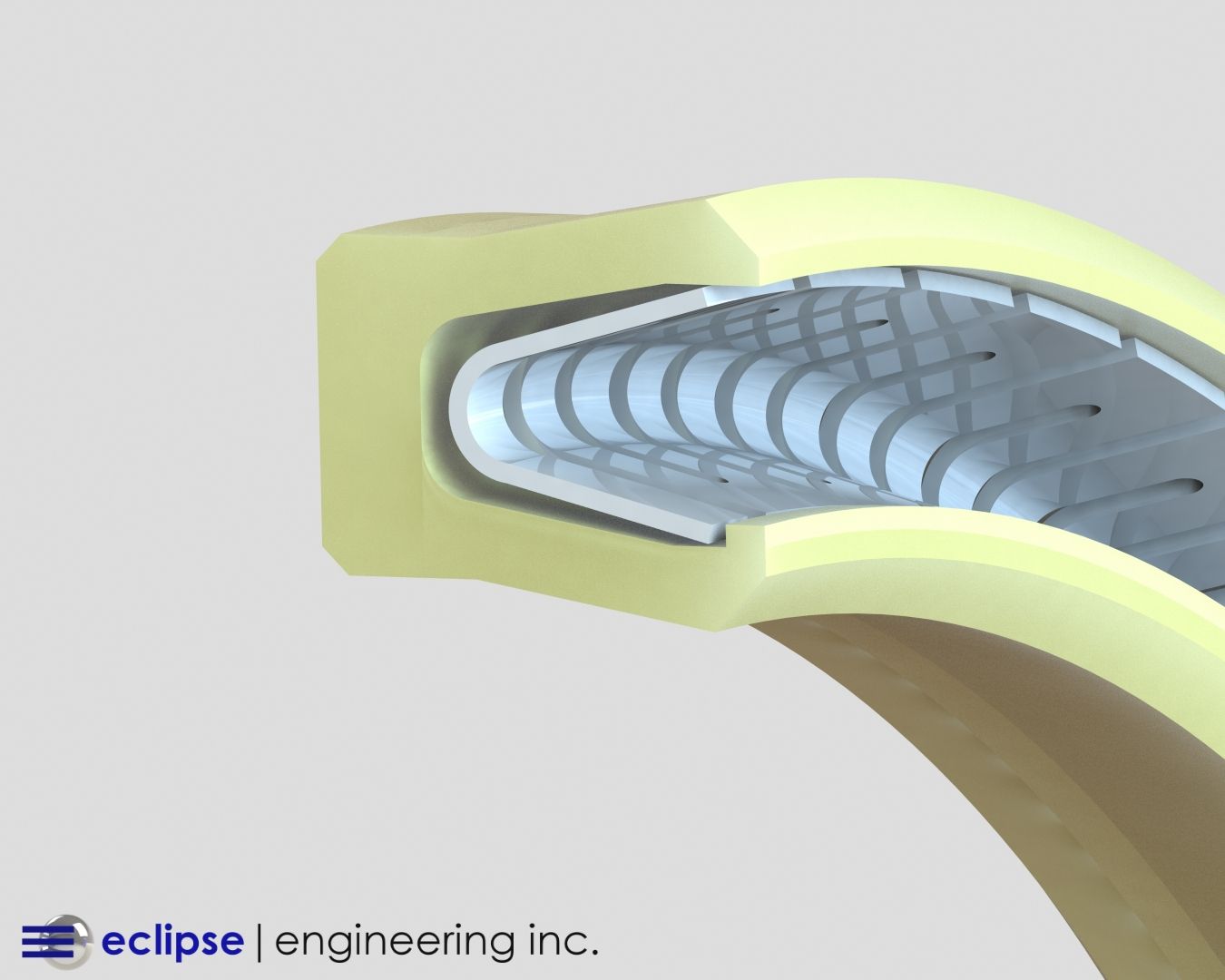

V-Spring is made from thin strips of sheet metal—typically 301 stainless steel—formed into a V shape. Alternating relief cuts along the V allow it to be bent into a circular form. This design functions like a leaf spring within the seal jacket, which is why it's often referred to as a

Cantilever V-Spring.

The spring’s energy and load are concentrated at the tips of the V, aligning with the seal jacket’s geometry to create a focused point-load at the seal’s leading edge. This makes it particularly effective in reciprocating applications where both sealing and media exclusion or scraping are required.

When paired with a highly wear-resistant

material like UHMW-PE, the V-Spring becomes a powerful sealing solution for thick, viscous substances such as adhesives and epoxy resins. To enhance performance, multiple V-Springs can be stacked or nested within the seal jacket, increasing the spring load and providing redundant sealing contact points.

In addition to its performance benefits, the V-Spring is often selected for its cost-effectiveness, particularly in high-volume production. It is manufactured using progressive dies and punches, making it the most economical spring to produce in long spools. It can be easily cut to length and welded into a circle using simple resistance welding techniques. Eclipse fully welds each spring to ensure uniform load distribution, though it can function in a seal jacket unwelded.

For very high-volume applications with small diameters, a circular spring pattern can be etched directly into sheet metal and then formed into a V shape. This eliminates the need for cutting and welding, further reducing costs.

However, the V-Spring’s concentrated point-loading, while advantageous in some scenarios, can be a drawback in rotary applications where it may accelerate wear on both the seal and hardware. Its linear load curve means that spring force decreases as the seal wears, potentially leading to overloading at the start and underloading toward the end of the seal’s life.

Another limitation of the V-Spring is its susceptibility to permanent deformation if over-compressed or distorted, which can render it ineffective. This is a concern in high back-pressure environments, such as down-hole drilling, where unexpected pressure spikes can flatten the spring.

Lastly, V-Springs have limitations at smaller diameters. As the diameter decreases, the inner tabs of the V can overlap and crowd the inner circumference, restricting their use in compact designs—an area where Canted Coil and Helical springs perform better.

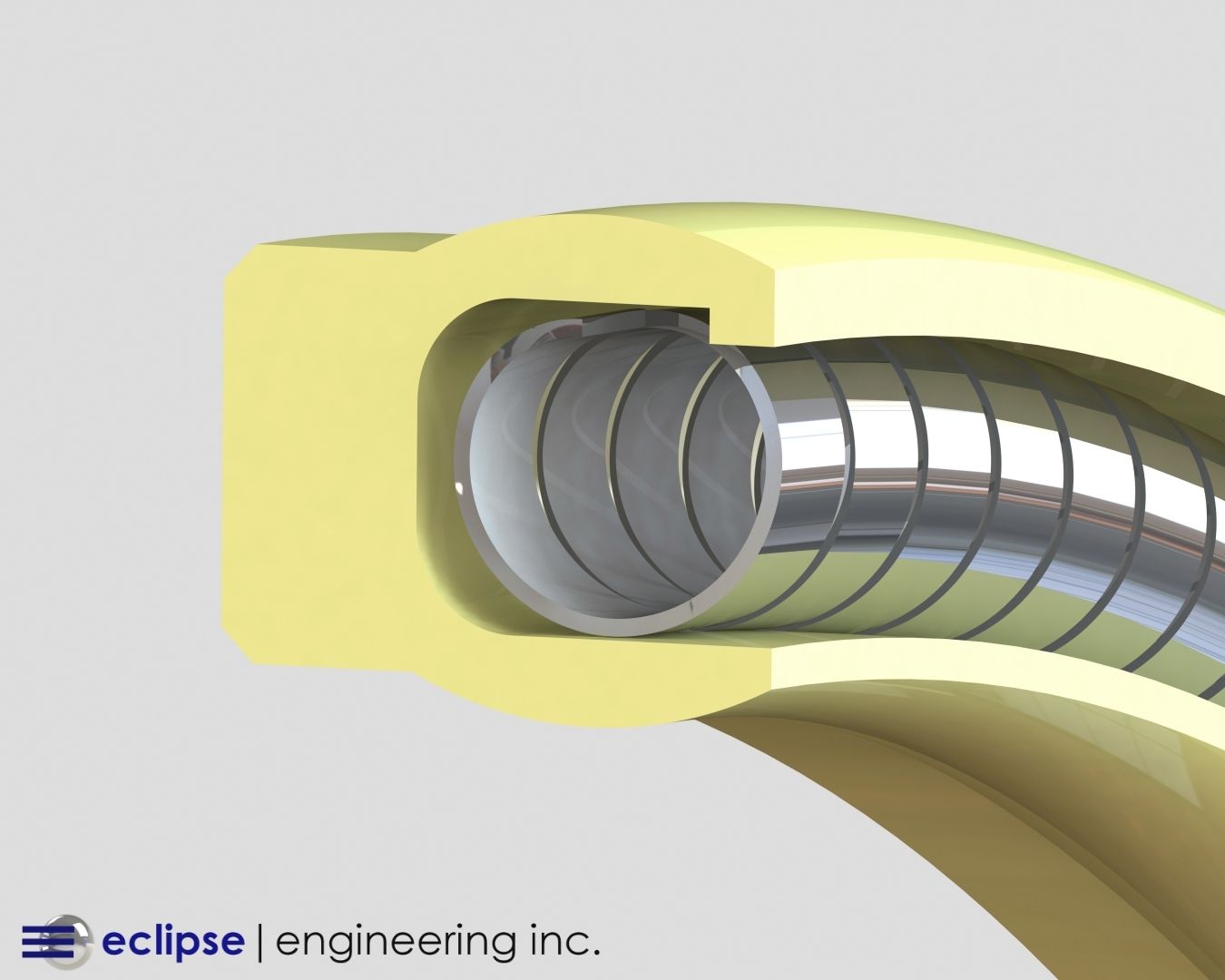

Helical

Helical Spring was actually the first spring type to be developed in the history of

spring energized seals. It consists of a thin ribbon of sheet metal curled into a tight spiral to form a flexible tube. Helical spring is typically 17-7 Stainless steel whereas the other spring types are usually 300 series stainless steel.

As shown in Figure 1, helical has a very steep, linear load curve. It has the highest loading of all the spring types, but also the smallest deflection range. The high load can be an advantage in specific applications.

Helical is most often used in static face seal applications. Especially in cold temperatures and cryogenics. This is where the high loading helps ensure the seal is in contact with the faces of the hardware despite shrinkage of both the seal and hardware and stiffening of the jacket material.

Helical is the most delicate of all the spring types, it is easy to yield if improperly handled or over compressed. This combined with its small deflection range means it is almost never used in dynamic applications. It is also not recommended for applications with frequent pressure cycling or situations where the seal needs to be uninstalled and reinstalled in the hardware multiple times. In this sense, helical spring seals can almost be thought as “crush gaskets."

If there is room in the hardware, nested cantilever V-springs can provide similar loading as helical springs but with a wider deflection range and added resilience against yielding.

Conclusion

So what spring is right for your application? If you want a short and sweet general answer: Rotary, use Canted Coil. Reciprocating, use Cantilever V-Spring. Static Cryogenics, use Helical. Of course, as we see above there are many aspects to consider and one solution will not always be the best choice.

The good news is that Eclipse is here to help. With decades of experience using every spring type in thousands of different applications, Eclipse is here to help specify the best spring for your unique application.

Contact us today if you have any questions or would like to start a project.