Seal Installation Best Practices for Reliable Performance

Proper seal installation is one of the most critical — and most overlooked — factors in sealing system performance. Even the most precisely engineered seal can fail prematurely if it is nicked, twisted, overstretched, or improperly seated during assembly. For manufacturers and engineers working with O-rings, PTFE seals, urethane components, and rigid polymer seals, installation must be treated as an integral part of seal design, not an afterthought.

This guide builds on Eclipse Engineering’s original insights and expands them with additional best practices, material-specific considerations, and tooling strategies to support consistent, repeatable seal installation across low- and high-volume applications.

Why Seal Installation Directly Impacts Performance

Seal failure is often traced back to installation damage rather than material selection or design flaws. Common installation-related issues include rolled O-rings, cut sealing lips, uneven compression, and permanent deformation caused by excessive stretching. These problems can result in leakage, accelerated wear, and shortened service life.

Installation-related risks increase as seal cross-sections become heavier, materials become less elastic, or production volumes rise. Understanding how different polymers behave under stress is essential when planning an installation method.

Designing Seals with Installation in Mind

Successful installation begins at the design stage. Gland geometry, lead-in chamfers, surface finishes, and allowable stretch must all support safe insertion without damaging the seal. Poor surface finish or sharp edges can easily cut or abrade polymer seals during installation, increasing the likelihood of early failure.

Surface finish is particularly important for rigid and semi-rigid polymers, where installation forces are higher, and material compliance is limited.

O-Ring Installation: Simple but Easy to Get Wrong

O-rings are among the most forgiving seals to install, but they are also frequently damaged due to complacency. In low-volume applications, O-rings can often be installed by hand. However, in higher volumes, installer fatigue increases the likelihood of rolling, twisting, or uneven seating.

Lubrication, when compatible with the application, can significantly reduce friction during installation. Care must be taken to avoid excessive stretching, particularly for small cross-sections or tight rod glands. Even minor installation defects can lead to spiral failure or uneven wear over time.

Material-Specific Installation Challenges

Different seal materials require different installation strategies, and applying a one-size-fits-all approach often leads to damage.

PTFE and PTFE Blends

PTFE seals present some of the greatest installation challenges due to their low elasticity and tendency to permanently deform if mishandled. Most PTFE blends exhibit elongations greater than 100%, which allows them to be stretched over pistons using bullet tools and pusher rings.

After installation, resizing tools are typically required to remove induced stretch and restore the seal to its intended geometry. These challenges are consistent with the broader advantages and limitations of PTFE materials.

Urethane and Elastic Polymers

Urethane seals and other elastic polymers can often be stretched into place without permanent deformation. While the risk of surface damage is lower than with PTFE, care is still required to avoid nicking the sealing surface or overstressing the material. Heavy cross-sections may still benefit from guided installation tools to ensure even seating.

Rigid Polymers

Rigid plastics such as PEEK, Torlon, and UHMW require careful alignment and controlled installation forces. These materials do not tolerate sharp edges or uneven loading well, making tooling and gland design especially important. Installation constraints should be evaluated alongside operating parameters during material selection.

Specialized Installation Tools and When to Use Them

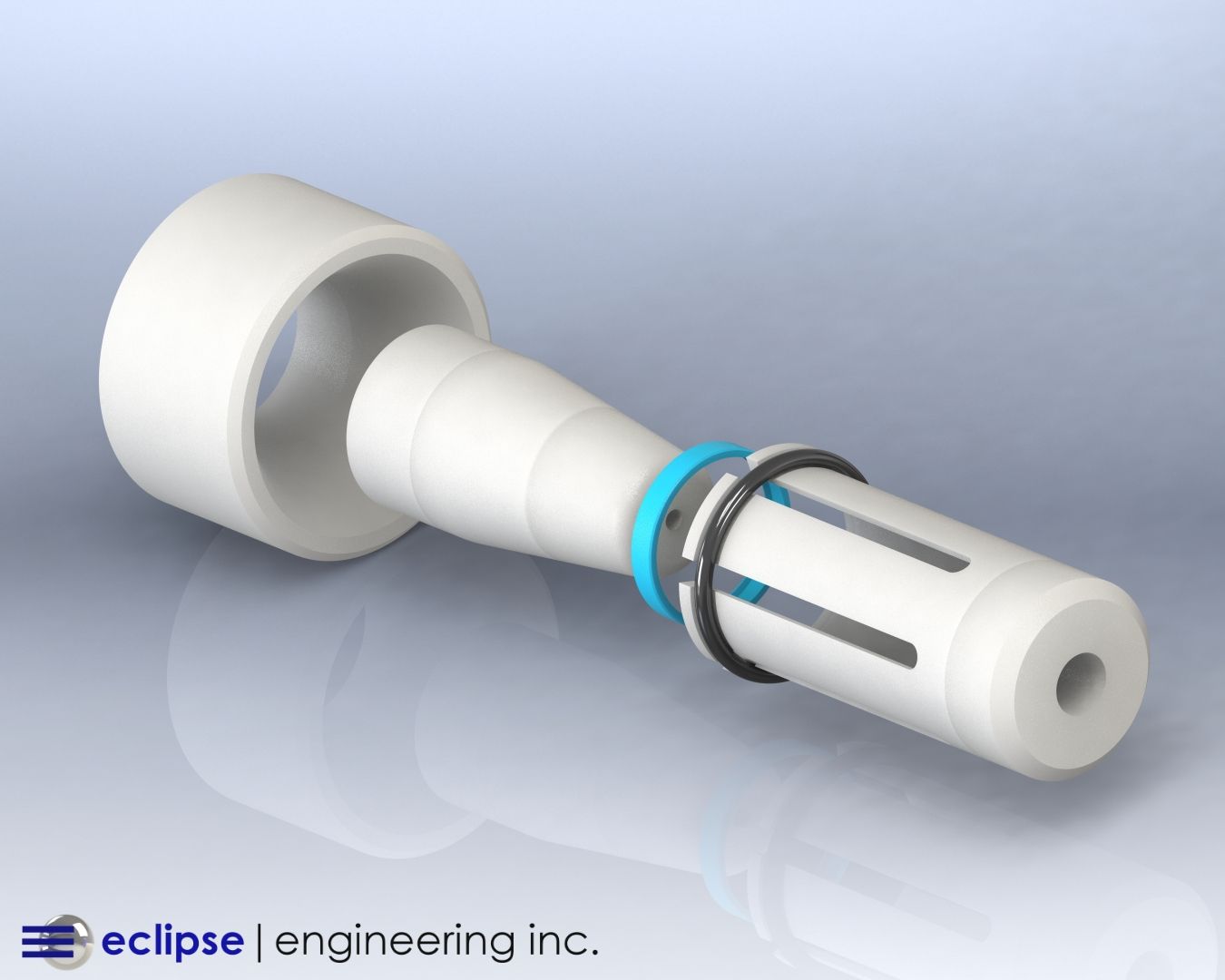

Installation tools are essential when working with high volumes, tight tolerances, or less forgiving materials. Bullet tools help guide seals over threads and sharp transitions, while pusher tools ensure uniform seating without point loading. Resizing tools are critical for PTFE seals, particularly after stretching during piston installation.

Using makeshift tools such as screwdrivers or metal picks introduces unnecessary risk and often results in surface damage that compromises seal integrity. Purpose-built tools help protect both the seal and the mating hardware while improving consistency across assemblies.

Installing Seals in Small Rod Glands

Small rod glands introduce unique challenges due to limited access and tight diameters. For O-rings, installers can often seat one edge of the seal and allow the rest to follow naturally. When access is restricted, a three-pronged tool can deform the seal into a kidney shape for insertion before gently seating it into the groove.

PTFE rings typically require additional care. After being formed into a kidney shape and inserted, an internal resizing tool is often necessary to restore the seal’s round profile and eliminate bends created during installation. Without proper resizing, sealing performance may be compromised.

Using Heat and Lubrication to Aid Installation

For PTFE and similar polymers, controlled heat can significantly improve pliability during installation. Heating seals in hot water softens the material temporarily, allowing it to be installed with less force. Because PTFE cools rapidly, installation must occur immediately after heating.

Lubrication can also reduce friction and minimize installation damage, even for materials that are not highly elastic. Any lubricant used must be compatible with both the seal material and the operating environment to avoid long-term performance issues.

Verifying Proper Seal Installation

Inspection is a critical final step in the installation process. Seals should be visually checked for nicks, uneven seating, or distortion. Directional seals must be oriented correctly, and glands should be free of debris or surface defects that could damage the seal during operation.

In high-reliability applications, verification procedures help ensure that installation variability does not undermine seal performance over time.

The Role of Training and Standardized Procedures in Seal Installation

Even with the correct seal design and installation tools, inconsistent installation practices can negatively impact performance. For high-volume or repeatable assembly processes, standardized installation procedures help ensure seals are handled, stretched, resized, and seated correctly every time.

Polymer seals such as PTFE, UHMW, and PEEK are especially sensitive to improper handling, which can introduce stress or deformation that shortens service life. Clear work instructions and basic operator training reduce variability, minimize damage, and improve consistency across production runs.

Treating seal installation as a controlled process — rather than an informal task — helps manufacturers improve reliability, reduce scrap, and maintain long-term sealing performance.

Ensuring Long-Term Seal Performance Starts with Installation

Seal installation is not a secondary consideration — it is a defining factor in how a seal performs in service. From material behavior and gland design to tooling and inspection, every installation decision influences reliability, wear life, and leakage control.

Eclipse Engineering regularly works with customers to develop installation strategies and custom tools that support repeatable, damage-free assembly.

By addressing installation challenges early, manufacturers can reduce scrap, improve consistency, and extend the service life of their sealing systems.

For expert guidance on seal installation, tooling, or material selection,

contact Eclipse Engineering to collaborate with our team on a solution engineered for long-term performance and reliability.