Temperature Ranges for Various Seal Materials: From NBR to PTFE

Selecting the correct seal material is one of the most critical decisions in any sealing application, and temperature is often the defining factor.

Operating outside a material’s allowable temperature range can result in hardening, softening, extrusion, accelerated wear, or catastrophic seal failure — even when pressure, surface finish, and gland design are otherwise correct.

From common elastomers like NBR to high-performance polymers such as PTFE, each sealing material responds differently to heat and cold. Understanding the temperature ranges of seal materials, how they behave at thermal extremes, and how temperature interacts with pressure and motion is essential for achieving long-term sealing performance.

Why Temperature Plays a Critical Role in Seal Performance

Temperature affects nearly every physical property of a sealing material. As temperatures rise, elastomers may lose elasticity, exhibit compression set, or undergo chemical degradation. Thermoplastics may soften, creep, or permanently deform. At low temperatures, materials can stiffen, shrink, or lose their ability to maintain sealing force against hardware.

In dynamic applications, frictional heat at the seal interface can significantly increase localized temperatures. Even when ambient system temperatures appear safe, surface speed and contact pressure can push materials beyond their thermal limits.

Installation practices also influence how well a seal tolerates thermal cycling, particularly when deformation or residual stress is introduced during assembly.

Elastomer Seal Materials and Typical Temperature Ranges

Elastomers are widely used due to their elasticity and ease of installation, but they generally offer narrower temperature windows compared to engineered polymers.

Nitrile Rubber (NBR)

NBR is one of the most common elastomers used for O-rings and static seals, thanks to its affordability and resistance to petroleum-based oils. However, its moderate temperature capability makes it susceptible to hardening at low temperatures and compression set at elevated temperatures, limiting its effectiveness outside general industrial environments.

Hydrogenated Nitrile (HNBR)

HNBR improves upon standard NBR by offering enhanced heat resistance, ozone resistance, and mechanical strength. It is often selected when higher operating temperatures or longer service life are required while maintaining elastomeric sealing behavior.

Fluorocarbon (FKM / Viton®)

FKM materials are frequently chosen for high-temperature sealing environments and chemically aggressive media. Their ability to maintain sealing force at elevated temperatures makes them a common upgrade when NBR or HNBR reach their limits, particularly in fuel, chemical processing, and aerospace applications.

Silicone Rubber

Silicone provides exceptional low-temperature flexibility and remains elastic where other elastomers stiffen. While its upper temperature range is comparable to FKM, lower tear strength and abrasion resistance often restrict its use in dynamic sealing applications.

Thermoplastic and Polymer Seal Materials

Thermoplastics rely on geometry, interference, and energization rather than elasticity to create a seal. These materials often outperform elastomers at temperature extremes.

PTFE (Polytetrafluoroethylene)

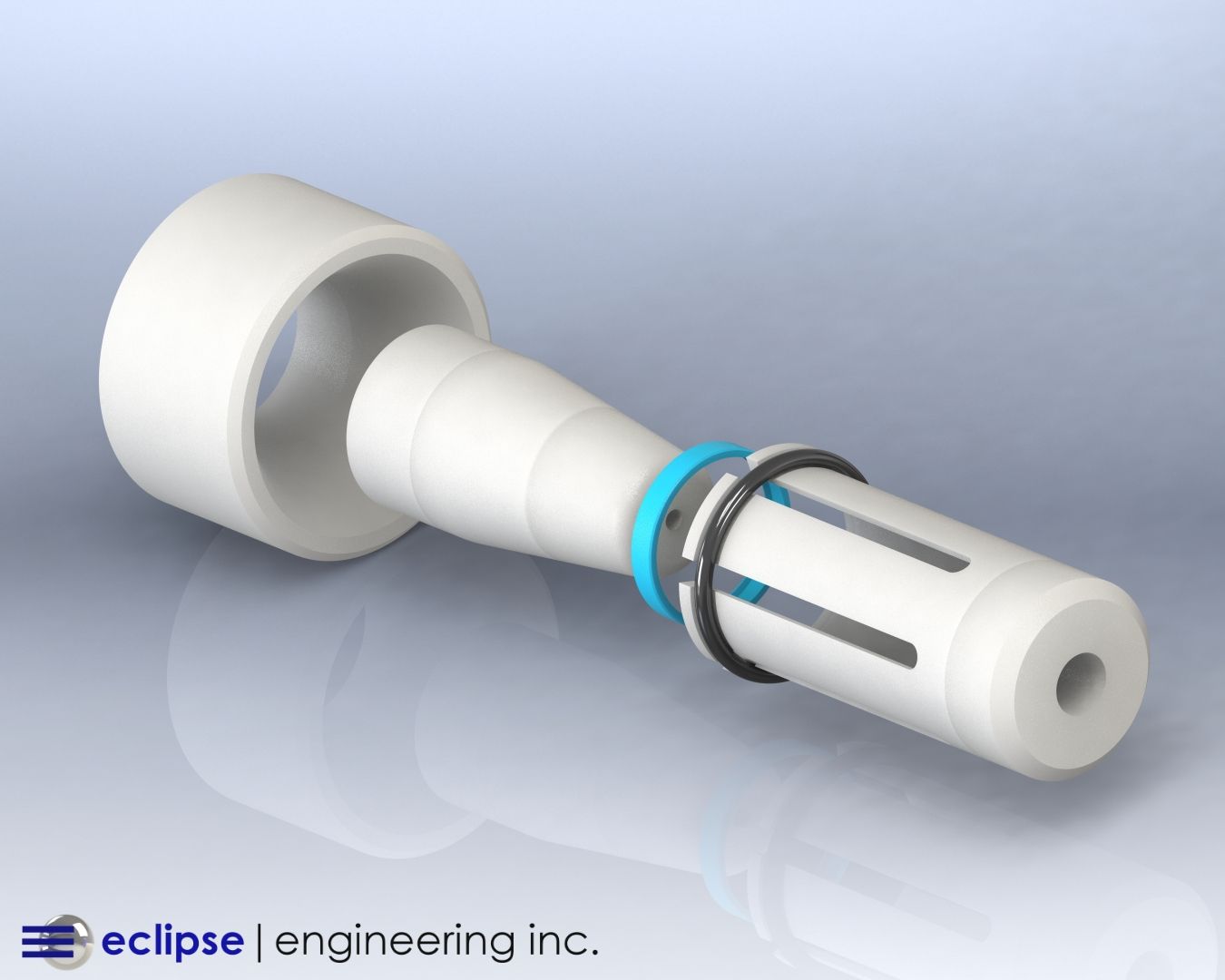

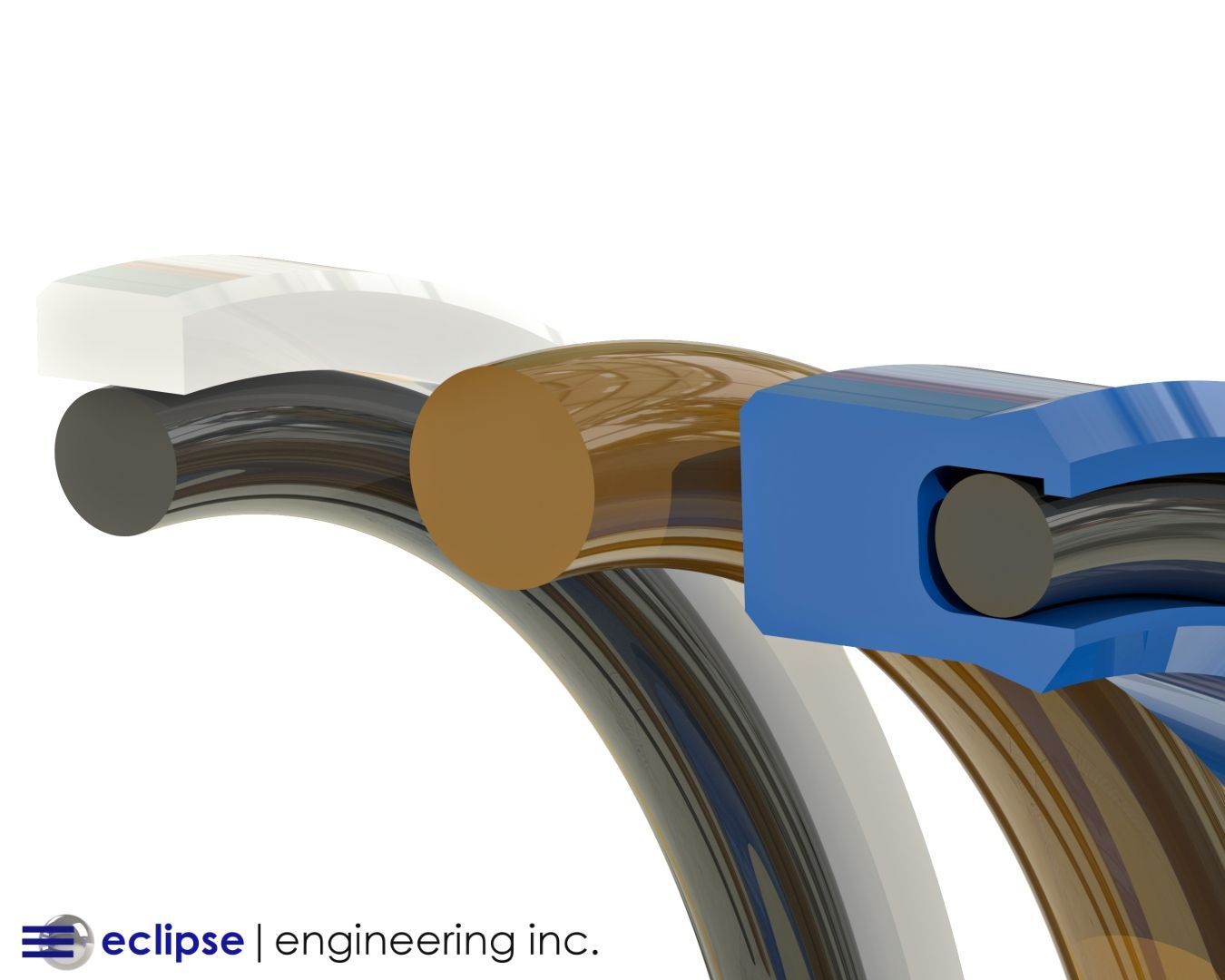

PTFE offers one of the widest operating temperature ranges of any sealing material and is nearly chemically inert. It performs reliably in both high-temperature and cryogenic applications where elastomers fail. Because PTFE lacks inherent elasticity, it is commonly used in mechanically energized designs such as spring-energized seals to maintain a consistent sealing force across wide temperature swings.

PTFE’s low coefficient of friction also helps minimize heat generation in rotary and reciprocating motion, extending seal life in demanding applications.

UHMW Polyethylene

UHMW provides excellent abrasion resistance and low friction, making it well-suited for reciprocating applications involving abrasive or particulate-laden media. Its relatively low upper temperature limit, however, restricts its use in elevated-temperature environments.

PEEK

PEEK is a high-performance thermoplastic capable of maintaining mechanical strength at elevated temperatures while offering excellent wear resistance and dimensional stability. It is often selected for high-temperature, high-pressure applications where stiffness and long-term reliability are critical.

Seal Material Temperature Range Comparison

| Material | Typical Temperature Range |

|---|---|

| NBR (Buna-N) | -40°F to +250°F (-40°C to +120°C) |

| HNBR | -40°F to +300°F (-40°C to +150°C) |

| FKM (Viton®) | -20°F to +400°F (-29°C to +204°C) |

| Silicone | -100°F to +400°F (-73°C to +204°C) |

| UHMW | -300°F to +180°F (-184°C to +82°C) |

| PTFE | -400°F to +500°F (-240°C to +260°C) |

| PEEK | -70°F to +480°F (-57°C to +250°C) |

Actual performance depends on pressure, motion, media, surface finish, and seal design.

Static vs Dynamic Sealing: Understanding Real Thermal Limits

Published temperature ranges are typically based on static conditions. In dynamic sealing — especially rotary motion — frictional heat can significantly reduce the effective operating temperature of a material.

For example, a seal material rated for 250°F static service may fail prematurely at much lower ambient temperatures when exposed to high surface speeds. PTFE-based solutions are often favored in these situations due to their thermal stability and low friction characteristics.

Installation methods also influence thermal performance, as improper stretching, rolling, or deformation can introduce stress that accelerates failure during thermal cycling.

The Impact of Thermal Cycling on Seal Materials

Many sealing applications do not operate at a single, steady temperature. Instead, seals are exposed to repeated heating and cooling cycles during startup, shutdown, washdowns, or process changes. This thermal cycling can be just as damaging as sustained high or low temperatures — and in some cases, even more so.

Elastomeric materials are particularly susceptible to thermal cycling. Repeated expansion and contraction can accelerate compression set, cause micro-cracking, or reduce sealing force over time. In dynamic applications, this loss of elasticity often leads to leakage during cold starts or premature failure at elevated temperatures.

Thermoplastics such as PTFE and PEEK handle thermal cycling differently. While they are less prone to compression set, they can experience creep or dimensional changes if gland designs do not properly accommodate expansion and contraction. This makes gland geometry, surface finish, and energization especially important in applications with frequent temperature swings.

Accounting for thermal cycling early in the design process helps prevent intermittent leaks, improves seal longevity, and ensures reliable performance across real-world operating conditions — not just steady-state temperature limits.

Low-Temperature and Cryogenic Sealing Considerations

Cold environments present unique challenges for sealing systems. Elastomers may lose elasticity and fail to energize properly at startup, while thermoplastics may contract or become brittle if the gland design does not account for thermal shrinkage.

Materials such as PTFE and UHMW are commonly used in cryogenic sealing applications due to their ability to remain stable at extremely low temperatures. Proper gland design and installation technique are essential to maintaining seal integrity under these conditions.

High-Temperature Sealing Challenges

At elevated temperatures, seals are exposed to increased risk of compression set, creep, chemical degradation, and accelerated wear. In these environments, material selection must be paired with appropriate gland geometry and, in many cases, mechanical energization.

Spring-energized PTFE seals and high-temperature polymers such as PEEK are frequently used to maintain sealing force when elastomers can no longer perform reliably.

Selecting the Right Seal Material by Temperature

While temperature is a primary driver in material selection, it should never be evaluated in isolation. Pressure, motion type, chemical exposure, installation method, and expected service life all play a role in determining long-term sealing success.

Material selection is most effective when these variables are considered early in the design process, reducing the risk of premature failure and costly redesigns.

Designing for Reliable Performance Across Temperature Extremes

Understanding temperature ranges for sealing materials from NBR to PTFE is fundamental to seal reliability. When properly specified, seals can perform across extreme environments for millions of cycles.

When misapplied, even advanced materials can fail prematurely.

Eclipse Engineering works with customers to evaluate how temperature interacts with the complete sealing system — from material selection and gland design to installation and long-term performance.

For assistance selecting the optimal seal material for your operating temperature range, contact Eclipse Engineering to collaborate on a solution engineered for durability, reliability, and performance.